%20Insertion%20version%20-%20PP01.jpg)

Kluczowe parametry

-

Maksymalny błąd pomiaru

Gas: 1.0% o.r. (10 to 100% o.f.s.), 0.1% o.f.s. (1 to 10% o.f.s.)

-

Zakres pomiarowy

20 to 733501 kg/h (44 to 1669340 lb/h)

-

Zakres temperatury medium

-40 °C to +180°C (-40 °F to +356°F)

-

Maks. ciśnienie procesu

-0.5 to 20 bar_g (-7.25 to 290 psi_g)

-

Materiały w kontakcie z medium

Materials for insertion tube

Stainless steel, 1.4404 (316/316L)

Process connections, process coupling

Stainless steel, 1.4404 (316/316L)

Sensing element

Unidirectional

Stainless steel, 1.4404 (316/316L)

Alloy C22, 2.4602 (UNS N06022);

Bidirectional

Stainless steel, 1.4404 (316/316L)

Reverse flow detection

Stainless steel, 1.4404 (316/316L)

Clamping rings

PEEK

PVDF

1.4404 (316/316L)

Flat ring seal

EPDM

FKM

Zastosowanie

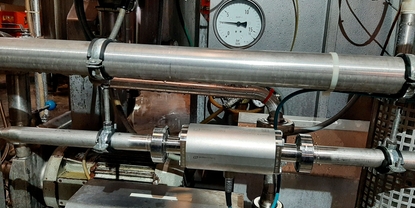

Opatentowana konstrukcja czujnika t-mass I zapewnia najwyższą stabilność pomiaru strumienia masy metodą termiczną. Kompensacja w czasie rzeczywistym wpływu zmian warunków procesu: temperatury, ciśnienia, kierunku przepływu oraz rodzaju gazu. Kompaktowy przetwornik zapewnia wysoką elastyczność obsługi i integracji z systemami: dostęp do urządzenia z jednej strony, rozdzielny wyświetlacz i ulepszone możliwości instalacji. Heartbeat Technology zapewnia wiarygodność pomiaru i możliwość weryfikacji stanu funkcjonalnego przyrządu.

Zasada pomiaru charakteryzuje się wysoką dynamiką i bezpośrednim pomiarem strumienia masy

Pomiar przepływu gazów użytkowych i procesowych oraz mieszanek gazów w rurociągach o przekroju okrągłym lub prostokątnym

Właściwości przepływomierza

Wersja zanurzeniowa przystosowana do rurociągów o wymiarach DN 80...1500 (3...60")

Pomiar dwukierunkowy; wysoka dokładność pomiaru

Opatentowany, wolny od dryftu czujnik o poziomie bezpieczeństwa funkcjonalnego SIL 2

Kompaktowa, dwukomorowa obudowa: można podłączyć maks. 3 moduły We/Wy

Podświetlany wyświetlacz z przyciskami "touch control" i dostępem poprzez WLAN

Możliwość podłączenia zewnętrznego wyświetlacza

Korzyści

-

Elastyczne i wygodne programowanie w oparciu o 21 standardowych gazów lub ich mieszaniny

Wysoki poziom kontroli procesu – najwyższa dokładność i powtarzalność pomiaru

Wiarygodny monitoring – wykrywanie zakłóceń procesu i przepływu wstecznego mierzonego medium

Elastyczny montaż – duży zakres średnic rurociągów o przekroju okrągłym lub prostokątnym

Pełny dostęp do danych procesowych i informacji diagnostycznych – szereg swobodnie konfigurowalnych modułów We/Wy i obsługa wielu standardów komunikacji obiektowej

Mniejsza złożoność i różnorodność – swobodna konfiguracja modułów We/Wy

Funkcje zaawansowanej autodiagnostyki i weryfikacji poprawności działania – Heartbeat Technology

Filmy

Segment Extended

-

Produkty zaawansowane

- Wysoka funkcjonalność i wygoda użytkowania

Poziom zaawansowania

Prostota obsługi

-

Produkty podstawowe

- Łatwe w doborze, montażu i obsłudze

Poziom zaawansowania

Prostota obsługi

-

Produkty standardowe

- Niezawodne, wytrzymałe i łatwe w utrzymaniu

Poziom zaawansowania

Prostota obsługi

-

Produkty zaawansowane

- Wysoka funkcjonalność i wygoda użytkowania

Poziom zaawansowania

Prostota obsługi

-

Produkty specjalistyczne

- Zaprojektowane z myślą o wymagających procesach

Poziom zaawansowania

Prostota obsługi

Zależna od urządzenia

| Segmentacja FLEX | Poziom zaawansowania | Prostota obsługi |

|---|---|---|

Segment Fundamental Zaspokoi Twoje podstawowe potrzeby pomiarowe |

Poziom zaawansowania

|

Prostota obsługi

|

Segment Lean Z łatwością obsłuży Twoje codzienne procesy |

Poziom zaawansowania

|

Prostota obsługi

|

Segment Extended Zoptymalizuje Twoje procesy dzięki innowacyjnym technologiom |

Poziom zaawansowania

|

Prostota obsługi

|

Segment Xpert Sprosta Twoim najbardziej wymagającym pomiarom |

Poziom zaawansowania

|

Prostota obsługi

Zależna od urządzenia |

Loading alternative products

Loading alternative products

-

-

Karta katalogowa (TI)

Proline t-mass I 300

Wersja polska - 09/2020

Termiczny przepływomierz masowy

EN PL 28/07/202305/07/202117/09/2020Język:

Polski

Wersja:

17/09/2020

Rozmiar pliku:

5.5 MB

Nazwa pliku:

TI01501DPL_0120.pdf

-

-

-

Instrukcja obsługi (BA)

Proline t-mass I 300 HART

Wersja polska - 09/2020

Termiczny przepływomierz masowy

EN PL 28/07/202305/07/202117/09/2020Język:

Polski

Wersja:

17/09/2020

Rozmiar pliku:

7.8 MB

Nazwa pliku:

BA01993DPL_0120.pdf

-

-

-

Karta katalogowa (TI)

Proline t-mass I 300

Termiczny przepływomierz masowy

EN PL 28/07/202305/07/202117/09/2020Język:

Polski

Wersja:

17/09/2020

Rozmiar pliku:

5.5 MB

Nazwa pliku:

TI01501DPL_0120.pdf

-

-

-

Instrukcja obsługi (BA)

BA Proline t-mass I 300

Thermal mass flowmeter

Modbus RS485EN PL 28/07/202305/07/202117/09/2020Język:

Angielski

Wersja:

28/07/2023

Rozmiar pliku:

6.8 MB

Nazwa pliku:

BA01995DEN_0323-00.pdf

-

-

-

Instrukcja obsługi (BA)

Proline t-mass I 300 HART

Termiczny przepływomierz masowy

EN PL 28/07/202305/07/202117/09/2020Język:

Polski

Wersja:

17/09/2020

Rozmiar pliku:

7.8 MB

Nazwa pliku:

BA01993DPL_0120.pdf

-

-

-

Parametryzacja urządzenia (GP)

Proline t-mass 300 HART

Thermal mass flowmeter

EN PL 01/07/202117/09/2020Język:

Angielski

Wersja:

01/07/2021

Rozmiar pliku:

2.1 MB

Nazwa pliku:

GP01143DEN_0221.pdf

-

-

-

Parametryzacja urządzenia (GP)

GP Proline t-mass 300 Modbus RS485

Thermal mass flowmeter

EN PL 15/03/202401/07/202117/09/2020Język:

Angielski

Wersja:

15/03/2024

Rozmiar pliku:

2.4 MB

Nazwa pliku:

GP01144DEN_0324-00.pdf

-

-

-

Skrócona instrukcja obsługi (KA)

Proline t-mass I

Termiczny przepływomierz masowy: czujnik

EN PL 05/07/202101/07/202117/09/2020Język:

Polski

Wersja:

01/07/2021

Rozmiar pliku:

1 MB

Nazwa pliku:

KA01443DPL_0221-00.pdf

-

-

-

Skrócona instrukcja obsługi (KA)

Proline 300 HART

Termiczny przepływomierz masowy: przetwornik

EN PL 05/07/202101/07/202117/09/2020Język:

Polski

Wersja:

01/07/2021

Rozmiar pliku:

1.9 MB

Nazwa pliku:

KA01444DPL_0221-00.pdf

-

-

-

Skrócona instrukcja obsługi (KA)

Proline 300 Modbus RS485

Termiczny przepływomierz masowy: przetwornik

EN PL 05/07/202101/07/202117/09/2020Język:

Polski

Wersja:

01/07/2021

Rozmiar pliku:

2 MB

Nazwa pliku:

KA01445DPL_0221-00.pdf

-

-

-

Wskazówki montażowe (EA)

Hot tap

t-mass I 300, 500-digital

EN PL 01/07/202131/07/2020Język:

Angielski

Wersja:

01/07/2021

Rozmiar pliku:

1.8 MB

Nazwa pliku:

EA01288DA2_0221.pdf

-

-

-

Wskazówki montażowe (EA)

EA Alteration Display module to Display module with WLAN

Proline 300, 400, 500, 500-digital

EN PL 01/01/202401/08/202131/07/202002/08/201902/01/2019Język:

Angielski

Wersja:

01/01/2024

Rozmiar pliku:

1.4 MB

Nazwa pliku:

EA01158DA2_0823-00.pdf

-

-

-

Wskazówki montażowe (EA)

EA Replacing cover, O-ring cover, Interface gasket

Proline 300, 500

EN PL 01/01/202401/06/202301/06/202131/07/202002/08/2019Język:

Angielski

Wersja:

01/01/2024

Rozmiar pliku:

9.6 MB

Nazwa pliku:

EA01143DA2_0723-00.pdf

-

-

-

Wskazówki montażowe (EA)

EA Replacing the electronics

Proline 300, 500, 500-digital

EN PL 01/01/202401/07/202301/06/202131/07/202002/08/2019Język:

Angielski

Wersja:

01/01/2024

Rozmiar pliku:

1.6 MB

Nazwa pliku:

EA01145DA2_0823-00.pdf

-

-

-

Wskazówki montażowe (EA)

EA Protective Cover connection compartment

Proline 300, 500, 500-digital

EN PL 01/01/202401/06/202301/06/202131/07/202002/08/2019Język:

Angielski

Wersja:

01/01/2024

Rozmiar pliku:

6.2 MB

Nazwa pliku:

EA01146DA2_0823-00.pdf

-

-

-

Wskazówki montażowe (EA)

EA Replacing the display module

Proline 300, 500, 500-digital, DKX001–

EN PL 01/01/202401/06/202131/07/202002/08/201902/01/2019Język:

Angielski

Wersja:

01/01/2024

Rozmiar pliku:

712.8 KB

Nazwa pliku:

EA01144DA2_0723-00.pdf

-

-

-

Wskazówki montażowe (EA)

EA Alteration with Display and operating module DKX001

Proline 300

EN PL 01/01/202431/07/202002/08/201915/09/201829/04/2016Język:

Angielski

Wersja:

01/01/2024

Rozmiar pliku:

1.3 MB

Nazwa pliku:

EA01163DA2_0523-00.pdf

-

-

-

Wskazówki montażowe (EA)

Flow conditioner

t-mass I 300, 500-digital

EN PL 31/07/2020Język:

Angielski

Wersja:

31/07/2020

Rozmiar pliku:

217.3 KB

Nazwa pliku:

EA01282DA2_0120.pdf

-

-

-

Wskazówki montażowe (EA)

EA Activating application packages, switching the I/O function, upgrading with additional I/O hardware

Proline 300, 400, 500, 500-digital

EN PL 01/01/202415/12/202101/08/202131/07/202002/08/2019Język:

Angielski

Wersja:

01/01/2024

Rozmiar pliku:

934.5 KB

Nazwa pliku:

EA01164DA2_0723-00.pdf

-

-

-

Wskazówki montażowe (EA)

EA Replacing Spare Parts

CNG-, LNG-, LPGmass, Proline 100, 300, 400 Index C, 500, 500-digital

EN PL 01/01/202415/12/202101/06/202101/06/202002/08/2019Język:

Angielski

Wersja:

01/01/2024

Rozmiar pliku:

1.9 MB

Nazwa pliku:

EA01018DA2_1523-00.pdf

-

-

-

Wskazówki montażowe (EA)

EA Replacing cover for remote display module, O-ring for cover

Proline 300

EN PL 01/01/202431/07/202002/08/201915/09/201801/08/2016Język:

Angielski

Wersja:

01/01/2024

Rozmiar pliku:

525.5 KB

Nazwa pliku:

EA01148DA2_0523-00.pdf

-

-

-

Wskazówki montażowe (EA)

EA Replacing the terminal connection

Proline 300, 500, 500-digital

EN PL 01/01/202401/06/202131/07/202002/08/201902/01/2019Język:

Angielski

Wersja:

01/01/2024

Rozmiar pliku:

4.3 MB

Nazwa pliku:

EA01161DA2_0723-00.pdf

-

%20Insertion%20version%20-%20PP01.jpg)

%20-%20CS01637X.jpg)

.jpg)